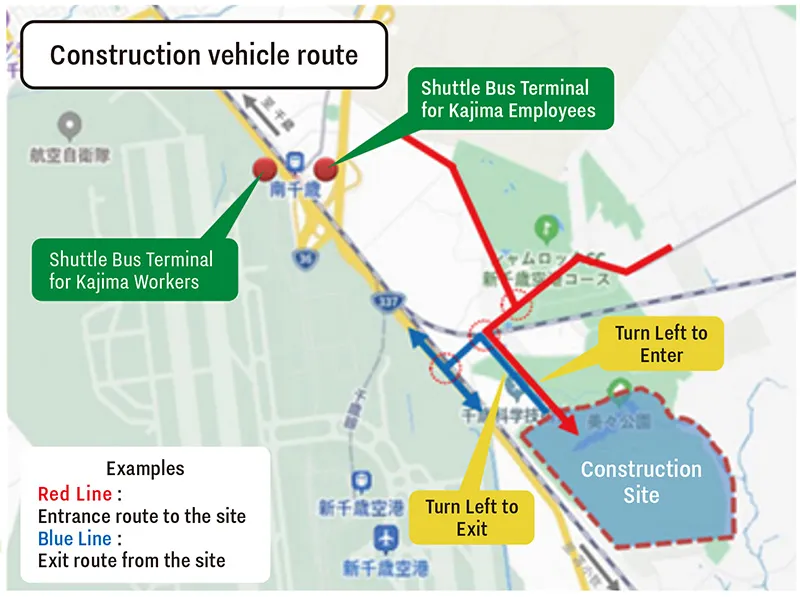

(1) Measures to prevent traffic congestion and accidents

- Traffic congestion during rush hours is reduced by prohibiting commuter vehicles from entering the site.

- Employees and workers are transported from Minami-Chitose Station or workers' housing (within the Izumisawa Industrial Park) to the site by a special large shuttle bus.

- By adjusting the timing of material deliveries, we can reduce peak hours and ease the concentration of construction vehicles, thereby balancing the number of vehicles.

- We have established optimal vehicle routes and deployed traffic controllers.

- To avoid traffic jams, the routes of the vehicles involved will avoid right turns.